-40%

4" Drive Wheel Assembly (3/4" shaft) for Belt Sander. High Quality-Set & Squared

$ 70.22

- Description

- Size Guide

Description

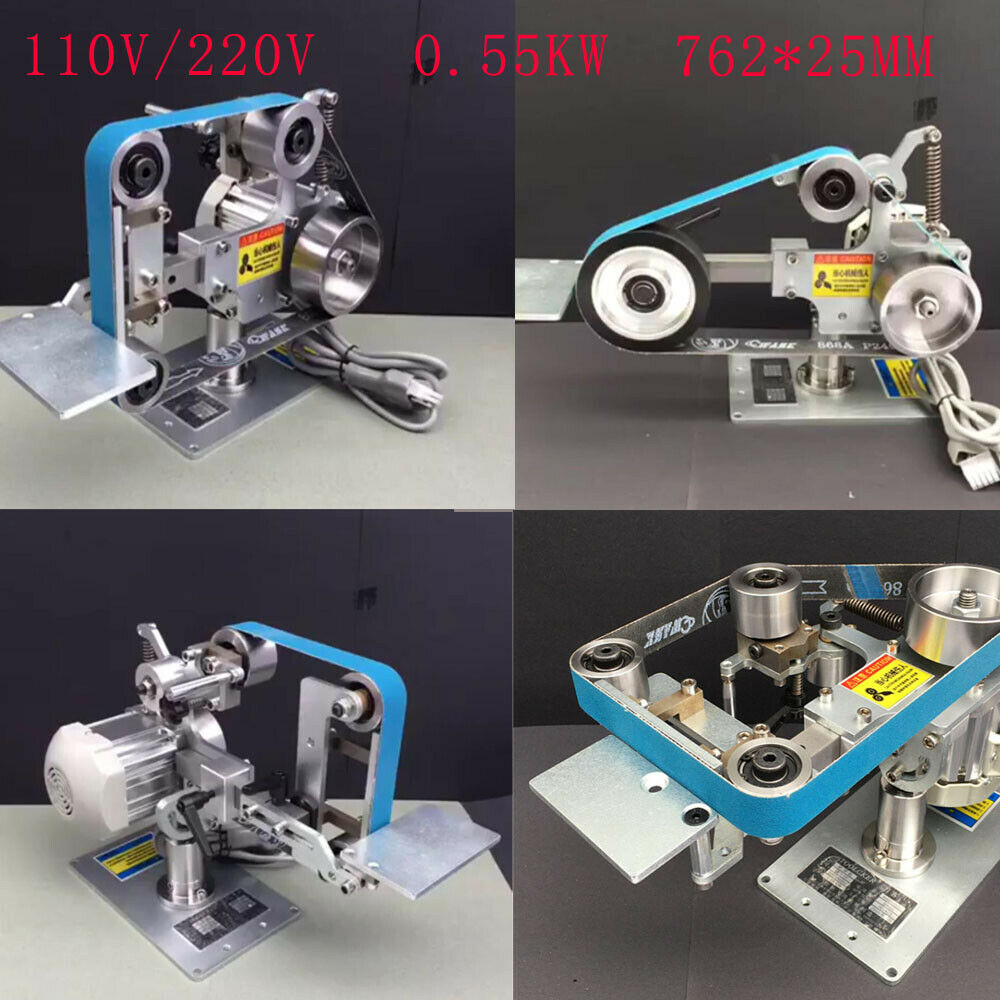

Please read first:Pillow blocks are self-adjusting, but this does not mean they won't wobble. For most applications this is OK, however on the belt sender it is a serious problem. Belt will not track properly. This is why so many people prefer direct

drive wheel

mount

on the motor shaft or opt for some kind of rigid assembly. I offer this Drive Wheel Assembly "Set & Squared" which means that the bearings are not just randomly put. This process takes positioning pillow block bearings parallel to each other and at the same time observing 90° angle between bearings and the shaft.

It is not an easy task and may be hard to perform in home-type workshop.

Knife Making: Heavy Duty 4" Belt Sander/grinder High Quality Drive Wheel Assembly in 3/4" or 7/8" shaft diameter sizes

.

Here we offer the proven design of our Drive Wheel Assembly.

For

balance, stability it is

built on solid 5/16" or 1/2" thick aluminum plate approximately 4" x 5" size. Two self-centering Pillow Block Bearing Units are installed parallel. This assembly can be mounted on Belt Sander Frame directly (or with the spacer if required). The plate has some pre-drilled and conveniently located mounting hole

The approximately 9" long Keyed Shaft

. It is secured in position by locking collars and provide very solid, steady, vibration free support for the drive wheel

running

at high speed.

The Drive Wheel is 4” OD x 2-1/4”

wide convex (domed for improved tracking) and precision machined from solid aluminum. Set screw and 3/16" key installed.

The belt pulley is designed for General Purpose A/4L,Type V-Belts, (1/2" belts). The 2"-3" outer diameter pulley's ratio will help to achieve proper sanding belt speed.

Horizontal or vertical mounting

Drive wheel will be removed from the shaft and wrapped separately for safe shipping.

Speed calculation

: If your 4" Drive Wheel rotates at 3450 RPM, then the belt surface

speed is 3613 SFPM (Surface Feet Per Minute).

The unit is highly adaptable and can be useful in numerous other projects as well.